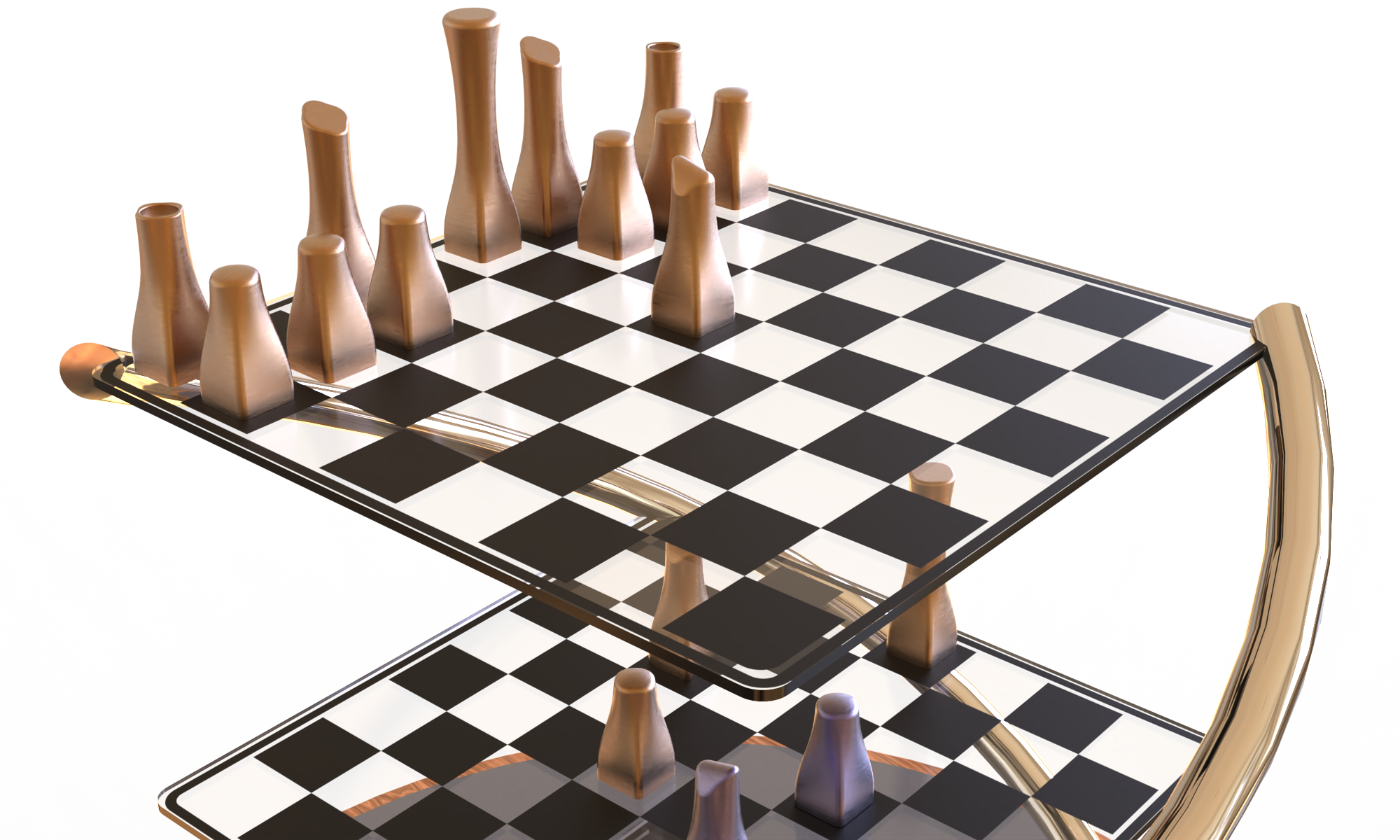

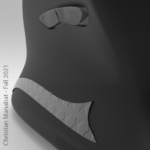

Modeling for 3D Printing Metal – Silverware Set

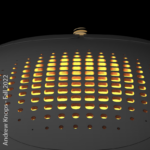

The assignment has three different focuses. The first is modeling using a multi-generational method to generate one form from another form. The second focus is using nTopology to generate a lattice form of the handle or a detail in the handle. For designers, it is a different way to model but generates interesting and dynamic forms. The final focus is using surface modeling to model the complex forms of the spoon, fork and knife.

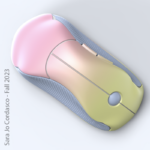

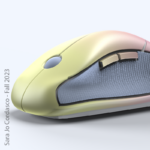

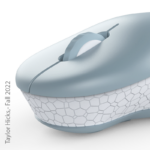

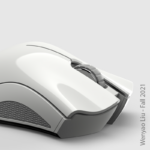

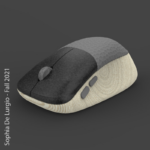

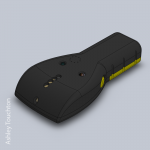

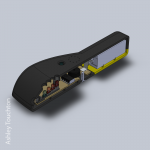

Modeling for 3D Printing Color – Gaming Mouse

For this assignment, students model a gaming mouse from start to finish. This will include defining the initial form as a t-spline and then converting it to a solid or surface. Buttons, pads, a scroll wheel and internal details will be added to complete the modeling. Through the different exercises, we learn how to create proper curves, sculpt basic forms, converts to solid, export areas out to detail in nTopology, and finish out the form.

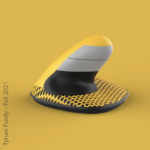

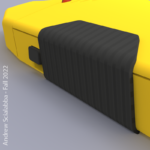

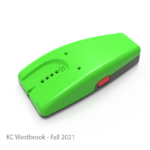

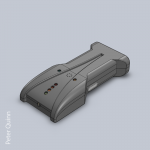

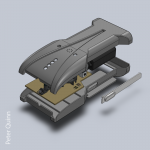

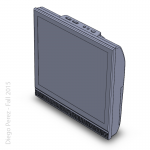

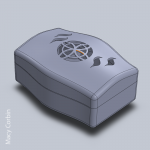

Modeling for Injection Molding – Stud Finder

This assignment is an example of modeling for injection molding process. Students are given the internal components of a stud finder device. They model a new form around the components and have to address the production issues for injection molding. This may include wall thickness, draft, transitions, etc.

Older Assignments

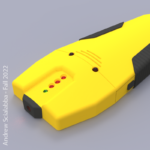

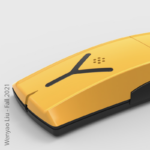

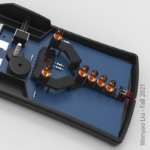

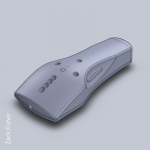

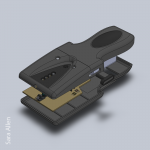

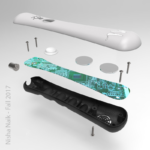

Laser Pointer

This assignment is an example of feature based modeling and assemblies. Students design their own laser pointer device that included internal components such as a circuit board, laser diode, battery and button. The form has to be shelled to create a wall thickness and include a vent hole, ribs and hardware bosses.

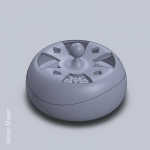

TENS Unit and Scanned Data

This assignment is an example of working with a master model, surfaces and scanned data. Students have their hand and arm scanned in the Body Scan Lab in the SoID. They design a custom fit brace for a TENS Therapy unit that is modeled using a master file. The brace is modeled using loft surfaces and trimmed to the final shape.

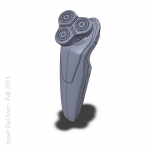

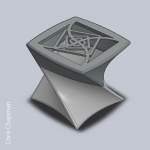

Existing Product Modeling

This assignment is another example of working with a master model and surfaces. Students pick an existing form that requires surfaces to model the shape. Then using a master file, the form is detailed out.

Animation

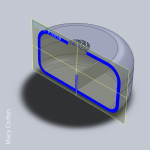

Jewel Cases

This assignment is another example of feature based modeling and assemblies. Students design their own jewel case. The form has to be shelled to create a wall thickness and include a vent hole, ribs and hardware bosses.